Deciphering the Engine’s Breath: A Comprehensive Guide to Testing a Manifold Absolute Pressure Sensor

Related Articles: Deciphering the Engine’s Breath: A Comprehensive Guide to Testing a Manifold Absolute Pressure Sensor

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to Deciphering the Engine’s Breath: A Comprehensive Guide to Testing a Manifold Absolute Pressure Sensor. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Deciphering the Engine’s Breath: A Comprehensive Guide to Testing a Manifold Absolute Pressure Sensor

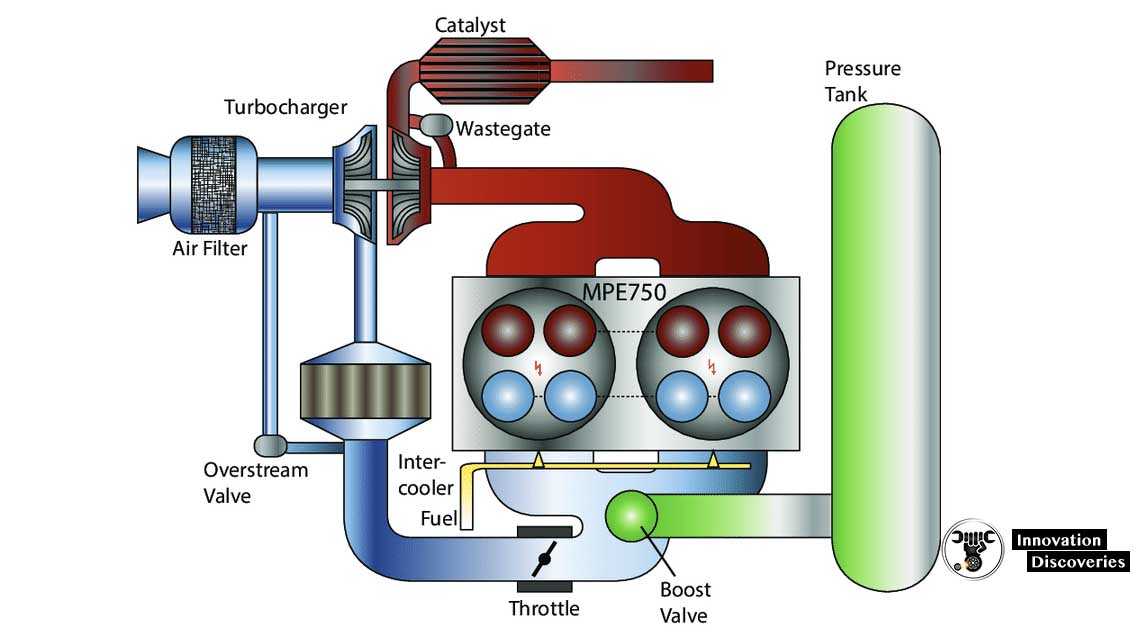

The manifold absolute pressure sensor (MAP sensor), a crucial component in modern automotive engine management systems, plays a pivotal role in gauging the engine’s "breath," providing vital information about the air pressure within the intake manifold. This data is then used by the engine control unit (ECU) to precisely regulate fuel delivery and ignition timing, ensuring optimal engine performance and fuel efficiency.

However, like any electronic component, the MAP sensor can malfunction, leading to a host of engine problems, including rough idling, stalling, poor acceleration, and even a check engine light. Identifying a faulty MAP sensor requires a systematic approach involving visual inspection, multimeter testing, and potentially, a pressure test.

Understanding the MAP Sensor’s Role:

Before delving into the testing process, it is crucial to understand the fundamental role of the MAP sensor in the intricate dance of engine operation.

The MAP sensor is essentially a pressure transducer, converting the intake manifold pressure into an electrical signal that the ECU can interpret. This pressure, measured in kilopascals (kPa) or inches of mercury (inHg), reflects the amount of air entering the engine’s cylinders.

- Fuel Delivery: The ECU utilizes the MAP sensor readings to determine the appropriate amount of fuel to inject into the cylinders. Higher manifold pressure indicates a greater air intake, necessitating a richer fuel mixture for optimal combustion.

- Ignition Timing: The ECU also relies on MAP sensor data to adjust ignition timing. A higher manifold pressure generally requires a slightly advanced ignition timing to maximize combustion efficiency.

Recognizing the Symptoms of a Faulty MAP Sensor:

A malfunctioning MAP sensor can disrupt this delicate balance, resulting in a variety of noticeable symptoms:

- Rough Idling: A faulty MAP sensor can lead to an erratic idle, causing the engine to shudder or vibrate.

- Stalling: In severe cases, a malfunctioning MAP sensor can cause the engine to stall, especially when accelerating or decelerating.

- Poor Acceleration: A faulty MAP sensor can hinder acceleration, making the vehicle sluggish or unresponsive.

- Check Engine Light: A malfunctioning MAP sensor will trigger a check engine light, accompanied by a diagnostic trouble code (DTC) related to the MAP sensor circuit.

- Fuel Economy Issues: A faulty MAP sensor can cause excessive fuel consumption due to incorrect fuel delivery.

Testing the MAP Sensor: A Step-by-Step Guide:

Testing a MAP sensor involves a combination of visual inspection, multimeter measurements, and, in some cases, a pressure test.

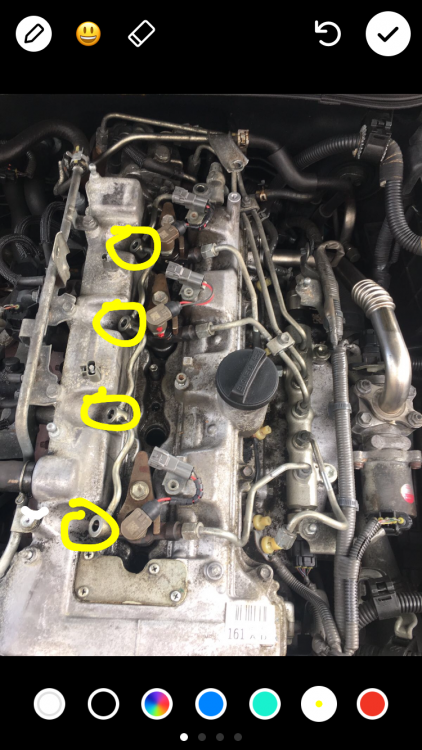

1. Visual Inspection:

- Inspect the Sensor for Physical Damage: Visually examine the MAP sensor for any signs of physical damage, such as cracks, corrosion, or loose connections.

- Check for Vacuum Leaks: Inspect the vacuum hose connected to the MAP sensor for any cracks, leaks, or loose connections. A vacuum leak can significantly affect the sensor’s readings.

2. Multimeter Testing:

- Check for Continuity: Use a multimeter to test the continuity of the MAP sensor’s electrical connections. This ensures a proper electrical path for the sensor’s signal.

- Check for Voltage: With the engine off, check the voltage at the MAP sensor’s power and ground terminals. The voltage should be within the manufacturer’s specifications.

- Perform a Resistance Test: The MAP sensor’s resistance should vary depending on the applied vacuum. Refer to the manufacturer’s specifications for the expected resistance range.

3. Pressure Test (Optional):

In some cases, a pressure test can further confirm a faulty MAP sensor. This involves applying a known vacuum to the MAP sensor and measuring the resulting output voltage. The voltage reading should correspond to the applied vacuum according to the sensor’s specifications.

Interpreting the Test Results:

- Visual Inspection: Any signs of physical damage or vacuum leaks indicate a faulty MAP sensor.

- Multimeter Testing: If the continuity, voltage, or resistance tests fail to meet the manufacturer’s specifications, it strongly suggests a faulty MAP sensor.

- Pressure Test: If the pressure test reveals discrepancies between the applied vacuum and the sensor’s output voltage, it confirms a malfunctioning MAP sensor.

Frequently Asked Questions (FAQs):

Q: What are the common causes of a faulty MAP sensor?

A: Common causes include:

- Physical damage: Impacts, vibrations, or corrosion can damage the sensor’s internal components.

- Vacuum leaks: Cracks or loose connections in the vacuum hose can affect the sensor’s readings.

- Electrical problems: Open circuits, short circuits, or corrosion in the wiring can disrupt the sensor’s operation.

- Environmental factors: Extreme temperatures, humidity, or contaminants can affect the sensor’s performance.

Q: Can I clean a MAP sensor?

A: While some MAP sensors are designed to be cleaned, it is generally not recommended. Cleaning the sensor can damage its delicate internal components and potentially worsen the problem.

Q: How can I determine if the problem is with the MAP sensor or the ECU?

A: If the MAP sensor tests within specifications but the engine still exhibits symptoms of a faulty MAP sensor, the problem may lie with the ECU.

Q: Can I replace the MAP sensor myself?

A: Replacing a MAP sensor is a relatively straightforward task for those comfortable with basic automotive repairs. However, it is essential to consult the vehicle’s repair manual or a qualified mechanic for specific instructions and procedures.

Tips for Testing a MAP Sensor:

- Use a high-quality multimeter: A reliable multimeter is essential for accurate testing.

- Refer to the manufacturer’s specifications: Always consult the vehicle’s repair manual or the MAP sensor’s specifications for accurate test values.

- Inspect the wiring carefully: Look for signs of damage, corrosion, or loose connections.

- Use a vacuum pump for pressure testing: A vacuum pump provides a controlled and accurate vacuum source for testing the sensor’s response.

- Consider a professional diagnosis: If you are unsure about testing the MAP sensor, consult a qualified mechanic for a professional diagnosis.

Conclusion:

Testing a manifold absolute pressure sensor is an essential step in diagnosing engine performance issues. By carefully inspecting the sensor, conducting multimeter tests, and potentially performing a pressure test, you can determine whether the MAP sensor is malfunctioning.

A faulty MAP sensor can significantly impact engine performance, fuel efficiency, and overall drivability. Promptly addressing a malfunctioning MAP sensor is crucial for maintaining optimal engine health and preventing further damage.

![]()

Closure

Thus, we hope this article has provided valuable insights into Deciphering the Engine’s Breath: A Comprehensive Guide to Testing a Manifold Absolute Pressure Sensor. We thank you for taking the time to read this article. See you in our next article!